We had another fun 3D print hangout last night.

Two newcomers and two veterans came, plus a few more who popped in later.

Just a reminder that we always start with 3D print 101, which takes about 45 minutes. The unstructured hang-out starts afterward. If you’re an experienced 3D-print veteran, it’s perfectly okay to skip the training and show up later. Bring your latest stuff; we’d all love to see it!

I brought my new rope-making gadget-set. I used ball thrust-bearings throughout, since I figured there would be a lot of friction once the rope strands were under tension. It was a great exercise in mating 3D printed parts to fit stock hardware–getting dimensions and clearances right is always a challenge.

I’m really happy with the result. It works great and makes a fun demo since it takes three people to use it. Nothing like having volunteers turn a crank and watch something new emerge before their eyes!

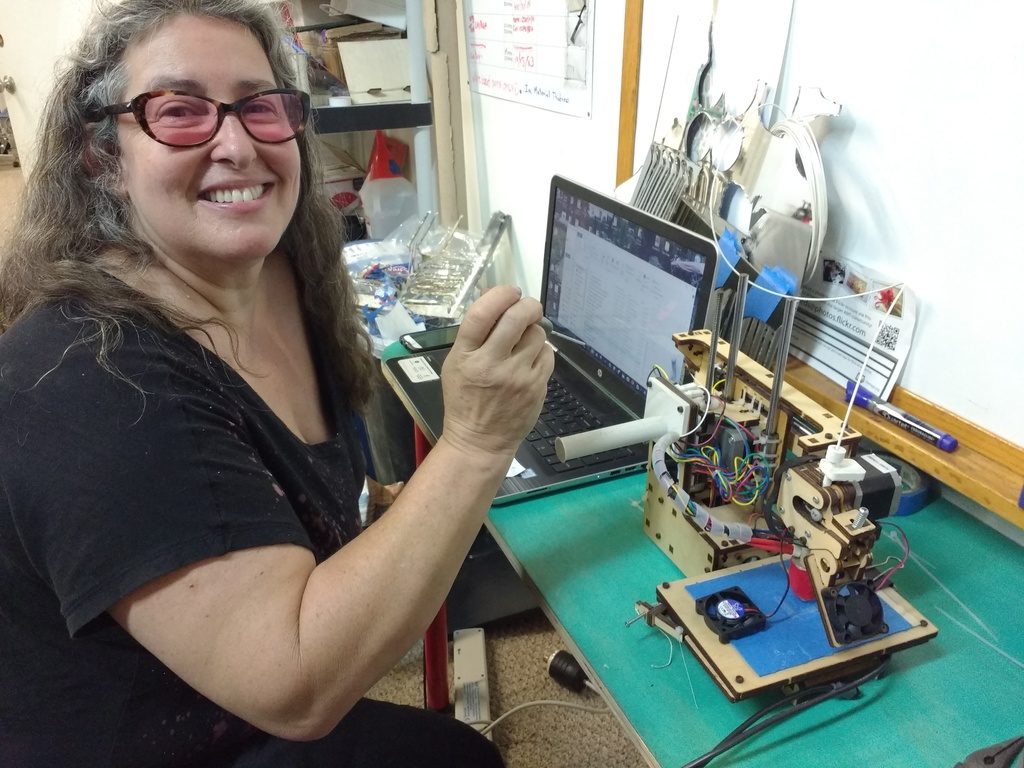

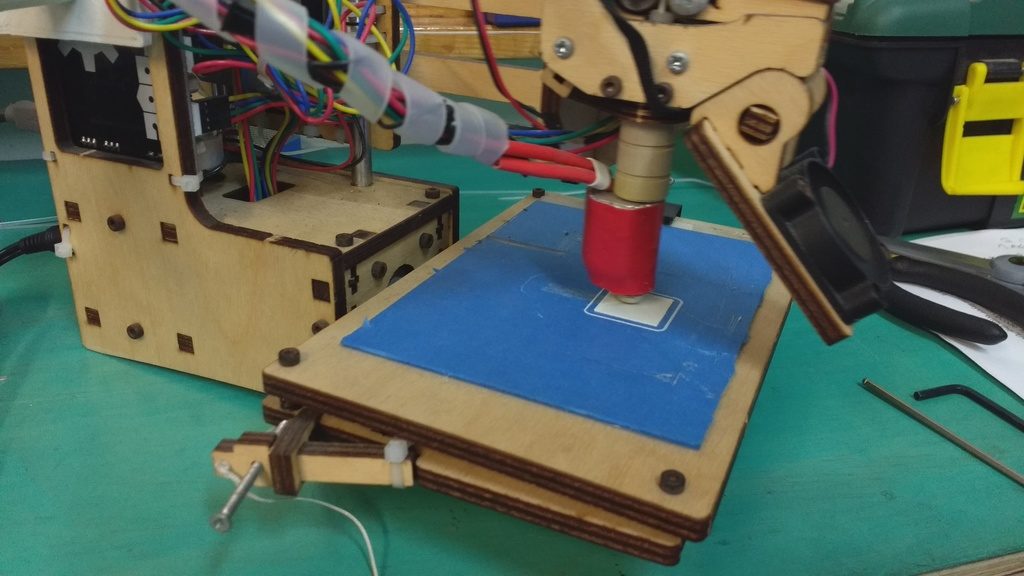

The big news of the night was Melissa’s new 3d printer! It’s an older laser-cut plywood PrintrBot simple she found online. It has a few miles on it to say the least; frankly I was not too optimistic. The gantry sagged, and I’d never worked with a ‘string drive’ before.

Still, all the electronics checked out; and the hot-end reached and held temperature just fine, so I set her to work tightening up and replacing a few dodgy-looking zip-ties.

That done, we configured Slic3r; leveled the bed and gave it a shot: The calibration cube printed just fine!

Even if it hadn’t worked out, an older project printer like this can sometimes still be a good deal for the components alone. The stepper motors seem to live forever, as do the electronics, linear bearings, etc. If you want a fun project; keep your eyes peeled for deals!

Don’t let inexperience be a barrier: I learned everything I know about it by surfing online. And of course, you can come to us if you need help.

Important note: our next hangout will be on Tuesday the 25th. That’s a day later than originally scheduled.